Overview of Products

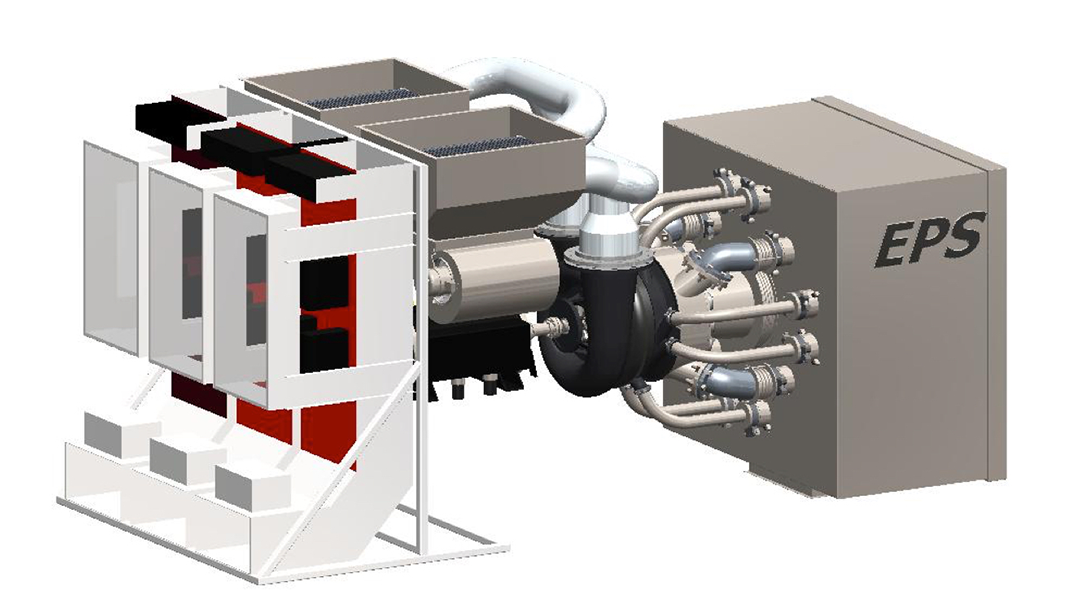

EPS’s ground-breaking technology is the development of advanced intercooled, recuperated turbine engines, optimized for small power generation while utilizing waste heat to generate usable heating. By using this system, EPS has been able to replicate the significantly higher efficiencies of much larger turbines (in excess of 75MW) into EPS’ smaller size turbines (under 5 MW).

These engines are portable (only 15’ X 7’ X 8’) and lightweight. They are designed to fit on a flatbed truck or inside a standard 20 ft. shipping container to be transported to where the fuel source is located or where the power is required. These turbines are scalable up to 5.0 MW and can be placed in series to form 20 MW power sub-stations.

Two Products – One Core Engine!

After investing more than 7,400 man hours, EPS is creating two products using the same core turbine engine technology to produce primary power – not just back-up power. Using a high commonality of parts, one version will be a Multi-Fuel 1.6 MW turbine that will run on any form of liquid or gaseous fuel including natural gas, propane, methane gas, high sulphur sour gas, synthetic gas or bio-diesel.

The other model will be a 1.2 MW Solid Waste Biomass turbine that will operate on any form of solid waste biomass, such as wood chips, wood pellets, bagasse, animal or commercial waste, or algae.

The EPS 1600 Multi Fuel Turbine

This Multi Fuel Turbine develops more clean, affordable electricity from existing and readily available fuel sources. It will run on any form of liquid or gaseous fuel; primarily natural gas, propane or methane gas. Natural gas in particular is currently relatively inexpensive, abundant and clean burning. Most importantly, a sophisticated developed grid infrastructure already exists for the distribution of natural gas in most developed nations.

The power produced by just one of these engines will generate enough electricity to run anything from 600 to 800 homes, an office complex, a university, a hospital or a shopping mall.

The EPS 1200 Solid Waste Biomass Turbine

This renewable resource powered turbine fulfills the world’s demand for affordable, sustainable energy.

It will be able to run on numerous types of solid waste biomass including wood chips and wood pellets, sawdust, agriculture residues, algae, bagasse, cellulosic landfill trash, animal and wastewater treatment residues and manufacturing process waste streams. Most biomass feed stocks are free, relatively low cost or even negative cost fuel sources. The turbine would be delivered to where the fuel source is located.

This engine avoids the costly gasification step (i.e. heating then cleaning the solid biomass into a liquid and then using this liquid to produce power). Instead, it will extract its power by burning the biomass at exceedingly high temperatures (up to 1,800F/1,000C approx.) which is known as Thermal Conversion.

A far as EPS is aware, no other Biomass Turbine engine exists using a thermal conversion process, making this a “game-changer.”

A few examples of the many uses of EPS engines

- Industrial

- Processing Industries (High Thermal Load)

- Pulp, paper, wood processing (biomass fuel source)

- Manufacturing Facilities & Centres

- District Power and Heating Centres (EU)

- Utility & Independent Power Producers

- Oil & Gas – Land and Offshore Installations

- Mining

- Commercial

- Hotels, Motels & Resorts with CHP

- Data Processing Centres

- Banks & Financial Institutions

- Hospitals & Emergency Care Facilities

- Shopping Malls

- Big Box Retail

- Government –

National & Local - Primary Government Buildings

- Community Shelters

- Emergency Services – Police & Fire

- Municipal Solid Waste and Recycling Facilities

- Waste Water Processing /Treatment Facilities

- Universities & Schools

- Homeland Security, FEMA & DoD

- Emerging High Growth Sectors

- Electric Vehicle Charging Stations

- Clean Water & Desalinization Facilities

- Apartment Complexes & Housing Developments

- Ports, especially Container Terminals

- Office Parks & High-Rise Office Buildings

- Remote Sites